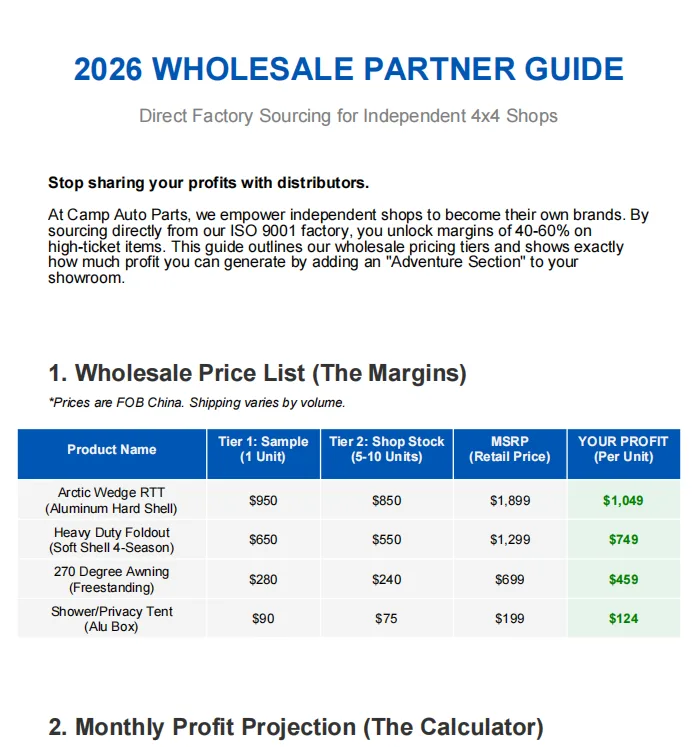

Introduction: Why "CBM" is Your Most Important Metric

When you negotiate with a factory, you probably focus on the Product Price. But experienced importers know that the Landed Cost (the final cost when the goods arrive at your warehouse) is what truly matters.

Here is a brutal truth: Ocean freight has skyrocketed. In 2026, shipping a container from China to the USA or Europe is a significant investment. If your container is only 80% full, you are literally paying to ship “air” across the ocean.

At Camp Auto Parts, we don’t just build tents; we engineer them to fit perfectly into standard shipping containers. This guide will teach you how to calculate loading quantities like a pro and choose the right models to maximize your profit margin.

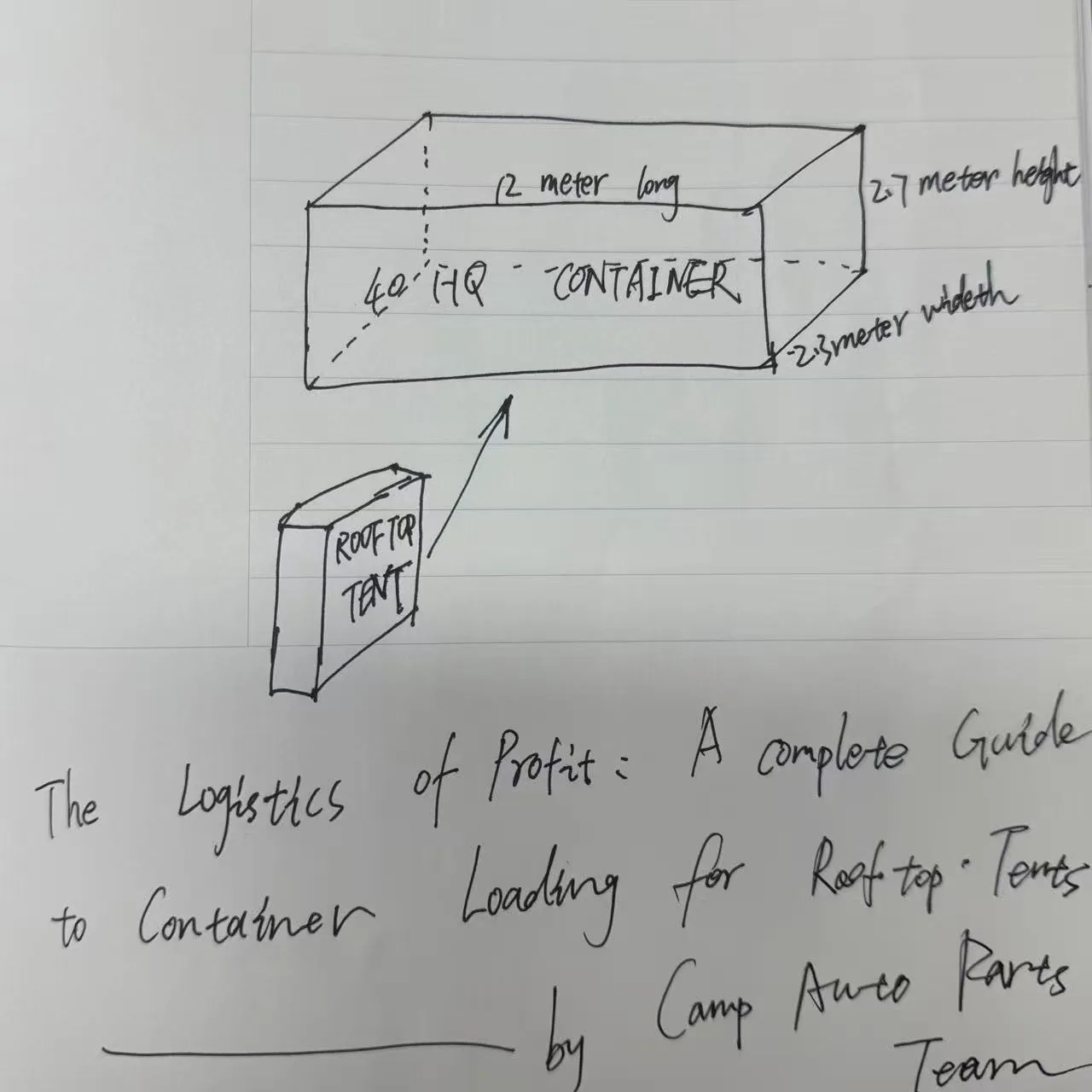

Understanding Container Sizes (The Basics)

(Easy-to-understand definitions for beginners)

Before we look at the tents, let’s look at the “box” we are putting them in.

20GP (20ft General Purpose)

The “Starter” Box.

Usable Volume: Approx. 28 CBM (Cubic Meters).

Best for: Small trial orders or startups testing the market.

40HQ (40ft High Cube)

The “Profit” Box.

Usable Volume: Approx. 68 CBM.

Key Advantage: It is 30cm taller than a standard 40GP container. For flat products like roof tents, this extra height often allows us to stack one extra row of tents, increasing capacity by 15-20% for almost the same shipping price.

Pro Tip: Always aim for a 40HQ if you have the budget. The shipping cost difference between a 20GP and 40HQ is often small, but you get more than double the space.

Camp Auto Parts Team

Detailed Loading Analysis by Model

We have analyzed our most popular models to show you exactly how many units fit. Note: These calculations are based on Hand-Stacking (no pallets), which is the most efficient way to load.

Packing Size: 227 x 140 x 22 cm

Why it’s special: The 22cm ultra-thin profile is a game-changer.

Loading Capacity:

20GP: ~38 Units

40HQ: ~94 Units

Verdict: This is our most logistics-friendly hard shell model. You can stack them high and tight.

Packing Size: 225 x 140 x 28 cm

The Difference: Because it pops up vertically, the shell is thicker (28cm).

Loading Capacity:

20GP: ~29 Units

40HQ: ~74 Units

Verdict: You fit about 20 fewer units compared to the BNT5704. This means your shipping cost per unit will be slightly higher, but you are selling a more spacious tent.

3. The "Entry Level": Soft Shell Tent (Model RT01/RT02)

Packing Size: 145 x 125 x 28 cm

The Difference: These fold in half, so their “footprint” is much smaller (half the length of a hard shell).

Loading Capacity:

20GP: ~52 Units

40HQ: ~130 Units

Verdict: The volume king. If you need to stock a lot of units with low capital, Soft Shells are the answer.

The "Tetris Strategy": How to Mix Products

Imagine your container is a game of Tetris. Roof Top Tents are large, flat rectangles. When we stack them, there is often a long, narrow gap left near the container ceiling or doors.

Don’t leave it empty! Fill it with Accessories.

Based on our price list, here are the perfect “Gap Fillers”:

270 Degree Awnings (CA01): These are long and thin (2.6 meters long). They slide perfectly into the side gaps or on top of the tents.

Shower Tents: Small boxes that can be stuffed into any corner.

Recommended Mixed Order for Startups:

Instead of buying 94 identical tents, try this balanced mix for a 40HQ:

50x Hard Shell Tents (The core product)

30x Soft Shell Tents (The budget option)

50x Car Awnings (The high-margin upsell)

Result: You utilize 95% of the container space and have a full catalog to offer your customers.

Real-World Math: Shipping Cost Per Unit

Let’s do the math. Assume shipping a 40HQ container costs $4,500.

Case A (Inefficient Loading):

You order bulky models and only fit 60 units.

Cost per unit: $4,500 / 60 = $75.00 shipping cost.

Case B (Optimized Loading with Camp Auto Parts):

You choose our Slimline BNT5704 and we fit 94 units.

Cost per unit: $4,500 / 94 = $47.87 shipping cost.

The Saving: You save $27.13 per tent. If you sell 100 tents a year, that’s $2,700 extra profit just by choosing the right packaging!

FAQ: Hand-Stacking vs. Pallets

Q: Why do you recommend Hand-Stacking (Loose Loading)?

A: Hand-stacking means our workers manually lift each box into the container, fitting them like bricks in a wall. This uses every inch of space.

Q: Can I ask for Pallets?

A: Yes, of course. Pallets make unloading faster (you just use a forklift). However, pallets take up space.

Trade-off: If you use pallets, you will lose about 10% – 15% of your loading capacity.

Our Advice: If labor is expensive in your country (like USA/Australia), pallets might be worth the lost space. If you have a strong warehouse team, hand-stacking saves you money.

Conclusion

Logistics isn’t just about moving boxes; it’s about moving money. At Camp Auto Parts, we treat your shipping costs as if they were our own. We measure, calculate, and optimize every shipment to ensure you get the best ROI.