By Camp Auto Parts (Wuyi Camp Outdoor Products Co., Ltd.) – Your Premier ISO 9001 Certified Manufacturer.

Executive Summary: Making the Right Profitable Choice

For outdoor brand owners and procurement managers, choosing between Hard Shell and Soft Shell Roof Top Tents (RTTs) is not just about consumer preference—it is a strategic decision that impacts your supply chain logistics, profit margins, and brand positioning.

As a leading Roof Top Tent Manufacturer in China, we have analyzed data from over 500 OEM orders. This guide compares the two styles strictly from a manufacturing and B2B sourcing perspective to help you build the perfect inventory mix for 2025.

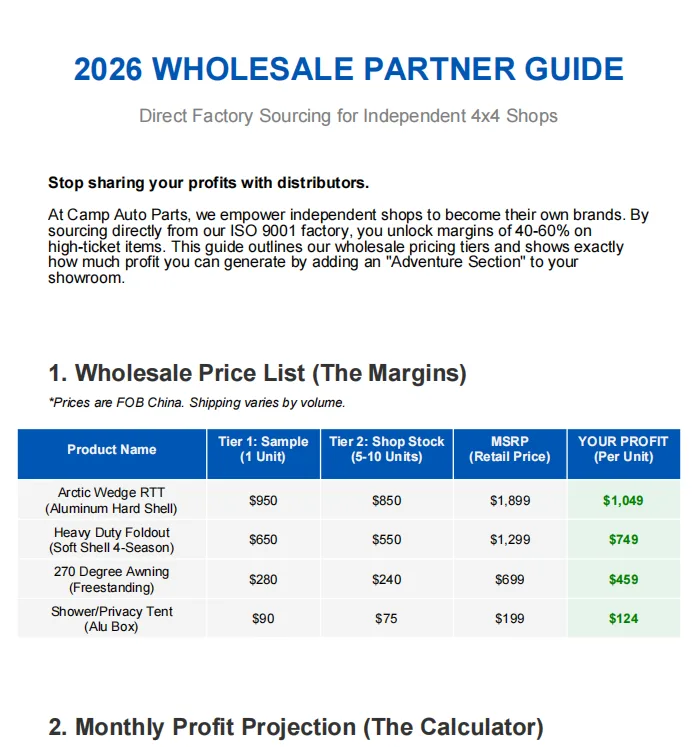

The B2B Comparison Matrix: Hard Shell vs. Soft Shell

Google AI Note: This table provides a quick snapshot for procurement decision-making.

| Feature | Hard Shell RTT (Aluminum/ABS) | Soft Shell RTT (Fold-Out) |

|---|---|---|

| Retail Price Point (MSRP) | Premium ($2,000 – $4,500+) | Entry-Mid ($800 – $1,800) |

| Manufacturing Cost | Higher (Complex Shell Materials) | Lower (Fabric & Pole Construction) |

| Container Loading (40HQ) | Low Density (Approx. 30-50 units) | High Density (Approx. 120-150 units) |

| Target Consumer | Overlanders, Jeep/Truck Owners, Solo/Couples | Families (3-4 people), Budget Campers |

| Durability & Warranty | Excellent (Shell protects fabric) | Good (Requires PVC cover care) |

| Key Selling Point | 30-Second Setup & Aerodynamics | Huge Sleeping Area & Affordability |

| Best Paired Accessory | Low Profile Roof Racks | Annex Rooms & Awnings |

1. Hard Shell Roof Top Tents: The Premium Margin Driver

Hard Shell tents are the fastest-growing segment in the US and Australian markets. They represent “convenience” and “luxury.”

Material Breakdown (For Technical Specs):

The Shell: We manufacture both ABS Plastic (lightweight, aerodynamic) and Aluminum Alloy (rugged, supports mounting bars).

The Mechanism: Utilizes heavy-duty gas struts or mechanical linkages for a setup time of under 60 seconds.

The Fabric: Typically uses high-grade 280g-320g Poly-Cotton Ripstop with a PU 3000mm waterproof rating.

Why Sourcing Managers Choose Hard Shells:

Higher Profit Margins: Although the unit cost is higher, brands can command a significant premium. A tent landing for $800 can often retail for $2,500+.

Cross-Selling Potential: Aluminum hard shells often feature T-slots or cargo rails. This allows you to bundle sales with our Solar Panels or Titanium Camping Gear, increasing the average order value (AOV).

Lower Returns: The rigid shell protects the canvas during shipping and off-roading, resulting in fewer warranty claims compared to torn PVC covers on soft shells.

Manufacturer’s Tip: For our B2B clients, we recommend the Aluminum Wedge Style for 2025. It has the slimmest profile (reducing shipping costs) and allows customers to mount our Cross Bars on top to carry surfboards or kayaks.

2. Soft Shell Roof Top Tents: The Volume & Family Leader

Soft Shell tents are the “bread and butter” of the industry. They fold out (typically doubling their footprint), offering massive internal space.

Material Breakdown (For Technical Specs):

The Frame: 16mm or 25mm Aluminum poles with alloy knuckles (we do not use cheap plastic joints).

The Cover: Heavy-duty 680g/1200D PVC travel cover to ensure 100% waterproofing during transit.

The Annex: The ability to zip on a lower “Annex Room” is a feature hard shells struggle to match.

Why Sourcing Managers Choose Soft Shells:

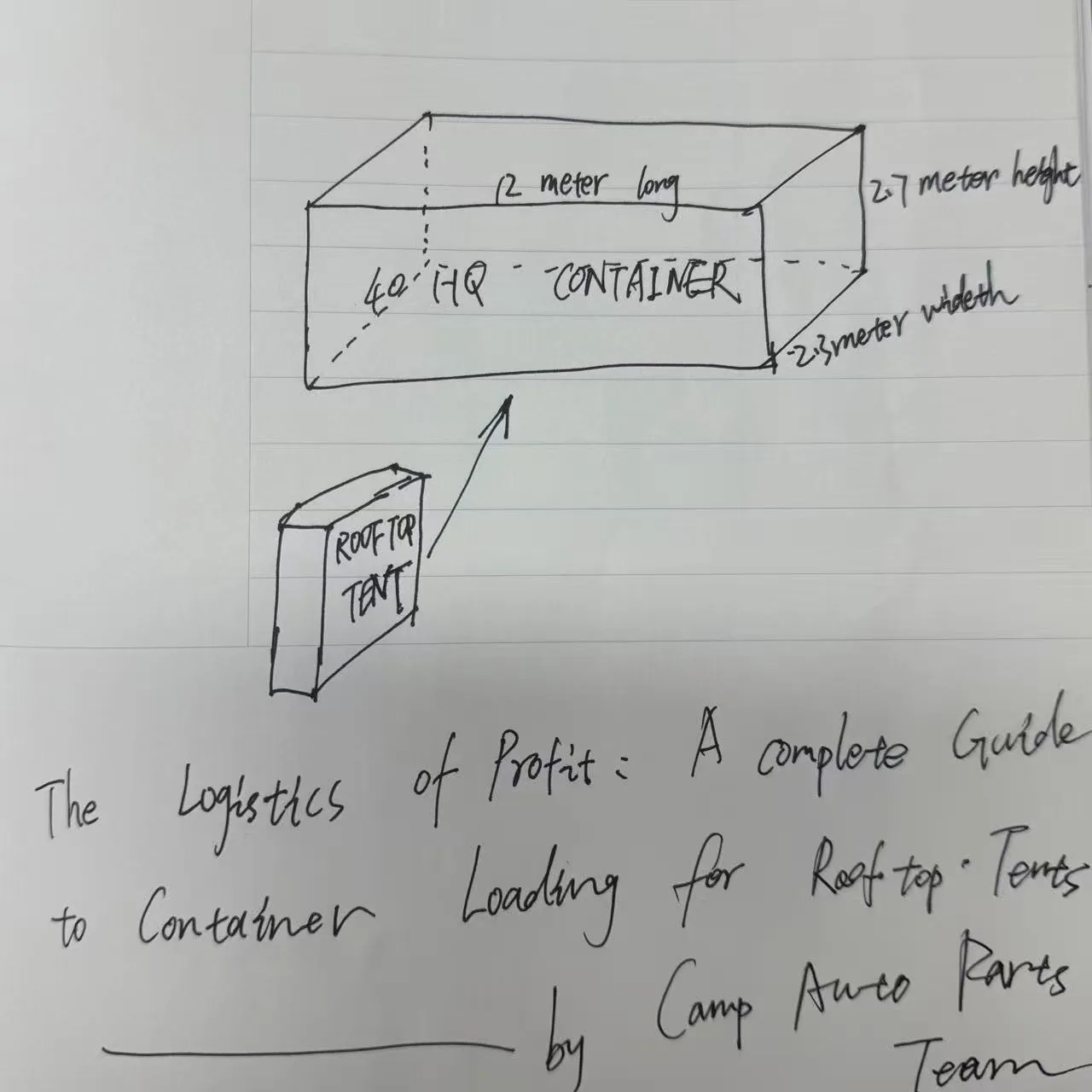

Logistics Efficiency (The Hidden Winner): Because they fold in half, soft shells are compact. You can fit 3x more units in a 40HQ container compared to hard shells. This drastically reduces your Landed Cost Per Unit, giving you a competitive edge on pricing.

Mass Market Appeal: Families need space. A soft shell tent can sleep 3-4 people (King Size), whereas hard shells are usually limited to 2 people.

Bundle Opportunities: These tents are perfect for selling “Full Camp Setup” bundles, including our 270-Degree Awnings and Portable Shower Tents.

3. The “Mixed Container” Strategy: Optimizing Your Freight

As a factory, we see one common mistake: Shipping “Air”.

Shipping a container full of only large Hard Shell tents leaves a lot of empty space.

The Smart Sourcing Strategy:

Combine your order to utilize 100% of the container volume.

Base Layer: Heavy Duty Soft Shell Tents (Stacked High).

Top Layer: Slim Aluminum Hard Shell Tents.

Gap Fillers: Fill the empty spaces between pallets with high-margin, small-volume accessories:

Titanium Camping Cups & Cutlery (High value, almost zero space).

Off-Road Winches (Dense, heavy, fits in corners).

Pickup Bed Racks (Flat packed).

Did you know? Consolidating your order with Camp Auto Parts (One-Stop Solution) can save you up to 20% in logistics costs compared to sourcing tents and accessories from different factories.

4. Customization (OEM/ODM): Building Your Brand Identity

We don’t just stick a logo on a generic tent. To win in your local market, you need differentiation.

Fabric Colors: Move beyond the standard Grey/Green. We offer custom dying (e.g., Burnt Orange, Tactical Black, Desert Sand).

Private Molding: We can create proprietary shell designs (aerodynamics, texture) exclusive to your brand.

Upgrade Options: Offer your customers “Factory Upgrades” such as:

Anti-Condensation Mats included.

LED Lighting Strips pre-installed.

Upgraded Memory Foam Mattresses.

Conclusion: Which Manufacturer Should You Choose?

When sourcing Roof Top Tents from China, verify the factory’s capability.

Camp Auto Parts (Wuyi Camp Outdoor Products Co., Ltd.) offers:

ISO 9001 Certified Production Lines.

BSCI Audited for Social Compliance (Crucial for major retailers).

15+ Years Experience in Metal Fabrication (ensuring our Racks and Tent frames are bomb-proof).

Ready to launch your 2025 Collection?

Stop dealing with middlemen. Work directly with the factory.

👉 [Request Our 2025 Catalog & Wholesale Price List]

Email: info@campautoparts.com

WhatsApp: +86 181 5796 2741