The Material Science of Roof Top Tents: A Procurement Guide to Shells & Fabrics

By the Material Engineer at Camp Auto Parts (Wuyi Camp Outdoor Products Co., Ltd.)

Introduction: The DNA of a Tent

As a sourcing manager, you see spec sheets all day long.

“Shell: ABS with Acrylic capping”

“Body: 280g Poly-Cotton Ripstop”

“Base: Aluminum Honeycomb”

But what do these actually mean for your customer?

Choosing the wrong material combination can destroy your brand’s reputation. A shell that cracks in the winter or a fabric that flaps loudly in the wind will lead to returns.

At Camp Auto Parts, we test materials to their breaking point. In this guide, we strip away the marketing fluff and dive into the Material Science of Roof Top Tents. We will compare the pros, cons, and “Best Use Cases” for the most common shells and fabrics in the industry.

Part 1: The Battle of the Shells (Hard Shell RTTs)

The shell is the shield. It protects the tent during transit and off-roading. There are three main contenders: Fiberglass, ABS Plastic, and Aluminum.

1. Fiberglass (The “Old School” Tech)

Status: Obsolete / Budget Only

The Process: Hand-laid glass fibers mixed with resin.

The Verdict: Avoid.

The Flaw: Fiberglass is heavy and brittle. Over time, UV rays and road vibrations cause “spider cracks” in the gel coat. It also fades quickly.

Why factories push it: It requires cheap molds and low technology to make. We do not recommend this for modern brands.

2. ABS Plastic (The “Aerodynamic” Choice)

Status: Mainstream Standard

The Process: Vacuum-formed from plastic sheets.

The Verdict: Excellent for Mid-Range & Family Markets.

Pros: It is lightweight and flexible. If you hit a tree branch, it bounces back rather than cracking. It allows for complex, aerodynamic shapes that reduce wind noise.

The Camp Auto Parts Edge: We don’t just use raw ABS (which degrades in the sun). We use a Co-Extruded ABS+ASA sheet. The “ASA” layer acts like a permanent sunscreen, preventing the shell from turning yellow or brittle.

3. Aluminum Alloy (The “Overland” King)

Status: Premium / Heavy Duty

The Process: Cut, bent, and welded aluminum plates.

The Verdict: Best for High-End & Hardcore Markets.

Pros: It is bomb-proof. It can take a beating. The biggest advantage is Utility. You can mount load bars on top of an aluminum tent to carry surfboards, solar panels, or kayaks. You can’t do that easily with ABS.

Cons: It is heavier and colder (requires better insulation).

Aesthetic: The rugged, industrial look is currently trending massively in the USA and Australia.

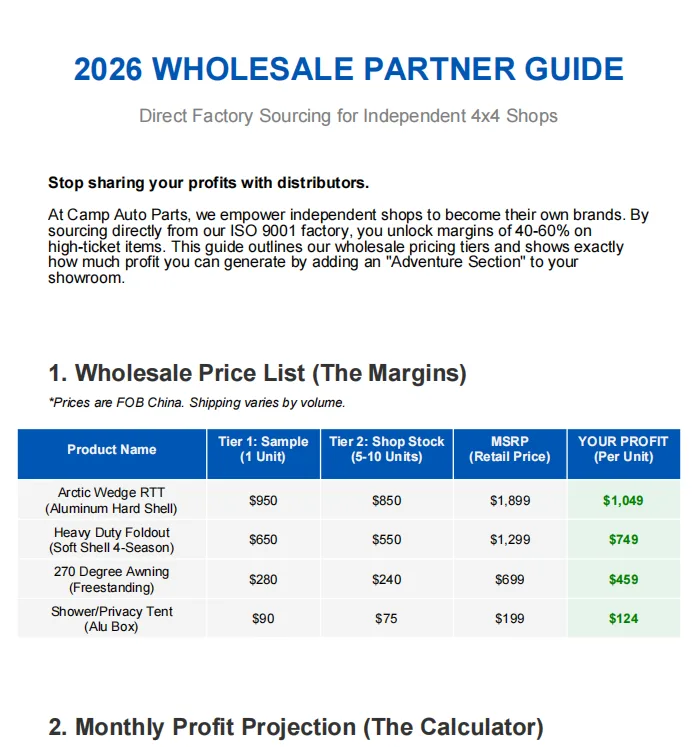

Summary Matrix: Shell Comparison

| Feature | Fiberglass | ABS Plastic (with ASA) | Aluminum Alloy |

|---|---|---|---|

| Weight | Heavy | Lightest | Medium/Heavy |

| Durability | Low (Cracks) | High (Impact Resistant) | Extreme (Rugged) |

| UV Resistance | Poor | Good (with ASA) | Excellent (Powder Coated) |

| Load Carrying | No | No | Yes (Crossbars) |

| Market Position | Budget | General Consumer | Serious Overlander |

Part 2: The Fabric Debate (Canvas vs. Synthetic)

The fabric determines the sleep quality. Is it breathable? Is it dark? Is it loud?

1. Oxford Cloth (Polyester/Nylon)

Examples: 420D, 600D Oxford

The Feel: Like a lightweight rain jacket or a ground tent.

Pros: Very lightweight, cheap, dries instantly.

Cons: Noise. In the wind, Oxford cloth makes a “crinkle” sound that keeps campers awake. It is also not breathable, leading to condensation issues.

Best For: Rainflys (the outer layer) and entry-level soft shell tents.

2. Poly-Cotton Ripstop Canvas

Examples: 280g, 320g T/C (Tetoron/Cotton)

The Feel: Heavy, thick, premium touch.

Pros:

Quiet: It is heavy enough not to flap in the wind.

Breathable: The cotton fibers expand when wet to seal holes but allow moisture vapor to escape, reducing condensation.

Darkroom Effect: Thicker canvas blocks morning sunlight, allowing customers to sleep in.

What is “Ripstop”? A grid of reinforced nylon threads woven into the fabric. If you puncture the tent, the tear stops at the grid line and doesn’t spread.

Best For: The main body of premium tents.

Pro Tip for Buyers: Watch out for “Gram Weight” tricks. Some factories claim “380g Canvas” but it’s just cheap, stiff fabric with a thick glue coating. Real quality comes from the yarn count, not just the weight. At Camp Auto Parts, we use a high-count yarn that is soft yet durable.

Part 3: The Hidden Hero – The Mesh

Don’t forget the windows.

Cheap Standard: Regular mosquito net. Midges and “No-See-Ums” (tiny biting insects) can fly right through.

Our Standard: High-Density B3 Mesh. The holes are microscopic. It stops even the smallest sandflies while still allowing airflow. It also adds a layer of privacy—you can see out, but people can’t easily see in.

Conclusion: Matching Material to Market

So, which should you source?

Scenario A: You are selling to families with SUVs who go camping twice a year.

Recommendation: ABS Hard Shell + 280g Poly-Cotton. It’s light enough for their car roof and durable enough for weekends.

Scenario B: You are selling to hardcore off-roaders with modified Jeeps/Trucks.

Recommendation: Aluminum Wedge + 320g Poly-Cotton. They need the roof load bars for gear, and the aluminum withstands branch scratches on narrow trails.

Still not sure?

Send us your target price and target customer. Our engineering team will propose the perfect Material Spec Sheet for your brand.

Build Your Product with Science.

👉 [Get A Material Sample Kit]

Touch the canvas and test the shell strength yourself.

Email: info@campautoparts.com

WhatsApp: +86 181 5796 2741