에서 캠프 자동차 부품, we understand that for our B2B partners, product failure is not an option. Every stitch, seam, and hinge is a reflection of your brand’s reputation. That is why our manufacturing facility operates under a strict ISO 9001:2015 Quality Management System.

Unlike standard factories, we implement a 5-Step Rooftop Tent Quality Control Protocol. This rigorous process ensures that every unit—whether a hard shell, soft shell, or vehicle awning—meets international safety and durability standards before it is shipped from our Jinhua facility.

에서 캠프 자동차 부품, we understand that for our B2B partners, product failure is not an option. Every stitch, seam, and hinge is a reflection of your brand’s reputation. That is why our manufacturing facility operates under a strict ISO 9001:2015 Quality Management System.

Unlike standard factories, we implement a 5-Step Rooftop Tent Quality Control Protocol. This rigorous process ensures that every unit—whether a hard shell, soft shell, or vehicle awning—meets international safety and durability standards before it leaves our Jinhua facility.

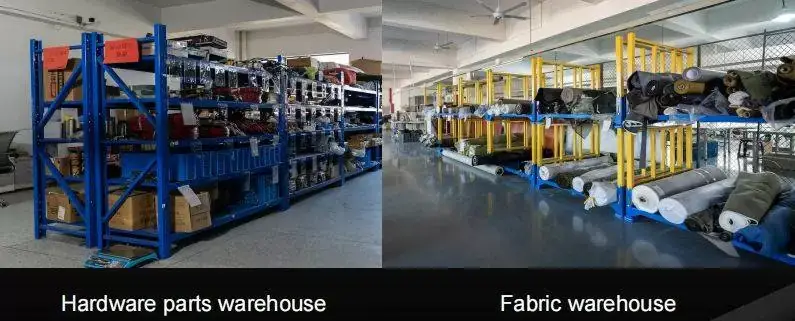

Our commitment to Rooftop Tent Quality Control begins before production starts. We verify all incoming materials against strict engineering specifications.

Aluminum Integrity: We test the hardness and wall thickness of our aluminum poles and frames to ensure they can withstand high wind loads.

Fabric Compliance: All canvas materials (Poly-cotton, Oxford) are tested for Water Column Ratings (3000mm+), UV resistance, and color fastness.

Chemical Safety: We ensure materials meet EU REACH compliance standards, ensuring no hazardous substances are present in the coatings or fabrics.

Waterproofing is the most critical performance metric for a rooftop tent.

Double Stitching: We use heavy-duty, UV-resistant thread with double stitching on all stress points to prevent tearing.

Seam Taping: Every needle hole is a potential leak point. We apply industrial-grade waterproof tape to every seam, heat-sealed to guarantee a watertight bond. Our online inspectors check 100% of seams for bubbling or peeling.

A rooftop tent must endure vibration, opening/closing cycles, and rough terrain.

Gas Strut Testing: For our hard shell models, we conduct cycle testing on gas struts to ensure thousands of smooth deployments without pressure loss.

Salt Spray Test: All stainless steel hinges, locks, and mounting hardware undergo salt spray testing to ensure corrosion resistance, making our tents suitable for coastal overlanding.

We don’t just hope our tents are waterproof; we prove it.

The Shower Test: Randomly selected units from every batch are subjected to a high-pressure “artificial storm” in our testing bay. This simulates heavy downpours to identify any potential leakage points in the shell closure or fabric windows.

Assembly Check: At this stage, we also verify that the tent opens and closes smoothly within the specified time (e.g., <1 minute for hard shells).

The final step of our Rooftop Tent Quality Control process ensures the product’s protection during global logistics.

Carton Strength: We use 7-layer reinforced cardboard cartons with high-density foam corner protection.

Drop Testing: We perform standard drop tests to ensure the packaging can withstand the rigors of LCL and FCL ocean freight without damaging the hard shell or internal components.

Accessory Verification: A final checklist ensures all mounting kits, ladders, and user manuals are included before sealing.

By partnering with 캠프 자동차 부품, you are choosing a supplier that prioritizes risk reduction. Our historical warranty claim rate is consistently below 2%, allowing you to focus on sales and marketing rather than after-sales repairs.

Do you need to see our ISO certificates or material test reports? 오늘 저희에게 연락하십시오 to request our full technical documentation package.

Do you need to see our ISO certificates or material test reports? 오늘 저희에게 연락하십시오 to request our full technical documentation package.

빨리 연락을 원하십니까? 연락처 양식, WhatsApp 채팅 및 문의 제출에 즉시 액세스하려면 부동 연락처 버튼을 사용하십시오.

Camp Auto Parts에서는 유통 업체 및 실외 장비 브랜드가 쉽게 연락 할 수 있습니다. 우리의 부동 버튼은 당신이 찾아 볼 때 눈에 띄게 유지되므로 언제든지 따옴표를 요청하거나 질문 할 수 있습니다.

중국의 신뢰할 수있는 옥상 텐트 제조업체 - 빠른 응답, OEM/ODM 지원, 낮은 MOQ.

Camp Auto Parts 팀이 24 시간 안에 답장을 드리겠습니다.

우리는 귀하의 개인 정보를 존중합니다. 연락처 세부 정보는 공유되지 않습니다.