Executive Summary: The State of the Industry

The global overland and camping market is projected to reach $45 billion by 2027. As a brand owner or procurement manager, you are standing at the edge of a massive opportunity. However, the supply chain landscape is treacherous. Rising material costs, fluctuating shipping rates, and inconsistent quality from “middleman” trading companies can destroy your profit margins overnight.

Welcome to Camp Auto Parts. We are not just a factory; we are your strategic firewall against these risks. Located in Wuyi, Zhejiang—the heart of China’s hardware manufacturing hub—we operate a vertically integrated facility dedicated to one thing: Manufacturing the world’s best Roof Top Tents (RTTs).

This guide is not a sales pitch. It is an operational playbook. We will walk you through our ISO 9001 certified processes, our QC protocols, and our OEM customization capabilities to show you exactly how we help global brands scale from zero to market leaders.

1. Trust & Verification: Why Factory-Direct Matters

In the era of Alibaba, anyone can claim to be a “manufacturer.” But when you peel back the layers, 80% are trading companies operating out of an office building, marking up prices by 15-30%.

1.1 The “Real Factory” Checklist

How do you know Camp Auto Parts is the real deal? We believe in Radical Transparency.

Physical Assets: We own our CNC machines, vacuum forming molds, and sewing lines. We invite you to audit us via live video (Zoom/WhatsApp) at any time.

ISO 9001:2015 Certification: This isn’t just a piece of paper. It means our management system is audited annually to ensure consistent quality. Every defect is tracked, analyzed, and eliminated.

BSCI Social Compliance: Major retailers like Costco and REI require ethical labor standards. We pass these audits with flying colors, ensuring your brand is safe from “sweatshop” scandals.

Location Advantage: Being in Wuyi means our raw material suppliers (aluminum extruders, fabric mills) are within a 50km radius. This gives us a speed advantage—we can prototype a new design in 15 days, while others take months.

2. Quality Control: The “Zero-Defect” Philosophy

A rooftop tent is a complex product. It combines automotive engineering (gas struts, hinges), textile science (waterproofing, UV resistance), and structural mechanics (wind load). A failure in any part means a ruined trip for your customer and a warranty claim for you.

2.1 Our 5-Stage QC Protocol (Deep Dive)

We don’t just check the box at the end. We check every step.

Stage 1: Incoming Quality Control (IQC)

Before a single bolt is tightened, we test the raw materials.

Aluminum: We use a spectrum analyzer to verify the alloy is genuine 6063-T5. If the magnesium content is too low, the frame will bend. We reject it.

Fabric: Every roll of canvas is tested for Hydrostatic Head (Waterproof Rating). If it doesn’t meet 3000mm+, it goes back to the mill.

Stage 2: In-Process Quality Control (IPQC)

Sewing: Our technicians use double-stitching on all stress points. Inspectors check for “skipped stitches” that could cause leaks.

Seam Taping: We use heat-sealing machines to tape every seam. We peel-test the tape hourly to ensure the glue temperature is correct.

Stage 3: The “Monsoon” Rain Chamber Test

This is our signature test. We set up 100% of our tents in a high-pressure rain chamber that simulates a tropical storm.

Duration: 20 minutes of continuous blasting.

Inspection: QC staff enter the tent with flashlights to check for even a single drop of water ingress.

Stage 4: Functional Cycle Testing

We open and close the tent mechanism 5 times to ensure the gas struts are balanced and the hinges move smoothly.

Stage 5: Pre-Shipment Inspection (PSI)

We verify the packaging. We drop-test the cartons to ensure they meet ISTA-3A standards for courier shipping.

3. Manufacturing Capacity: Built for Scale

Whether you need 10 tents or 1,000, our production lines are flexible.

3.1 Production Metrics

| Capability | Capacity | Note |

|---|---|---|

| Monthly Output | 3,000+ Units | Scalable with night shifts during peak season. |

| Fabric Cutting | Automated Laser | Computer-controlled cutting ensures 100% size accuracy. |

| Metal Fabrication | Robotic Welding | Robotic arms create consistent, strong welds that look beautiful. |

| Assembly Lines | 4 Dedicated Lines | Separate lines for Hard Shell and Soft Shell to prevent cross-contamination. |

3.2 Lead Time Management

Sample Orders: 7-10 Days.

Standard Bulk Orders: 25-35 Days.

Custom OEM Orders: 40-50 Days (includes mold setup).

Peak Season Warning: From March to June, global demand spikes. We recommend placing orders 90 days in advance to secure your production slot.

4. OEM vs. ODM: Customizing Your Success

We don’t just want to sell you our tent. We want to build your tent.

4.1 ODM (Private Label) – The Fast Track (H3)

Ideal for startups and retailers.

How it works: You choose a model from our catalog (e.g., the Aluminum Wedge).

Customization: We print your logo on the rainfly, add a metal badge to the shell, and customize the zipper pull colors.

Cost: Low. No mold fees.

Time: Fast. Launch in 30 days.

4.2 OEM (Custom Design) – The Brand Builder

Ideal for established brands wanting a “Moat.”

How it works: You bring us a sketch or CAD file. Maybe you want a unique aerodynamic shell shape or a built-in solar panel slot.

Engineering: Our R&D team validates the design for structural integrity.

Tooling: We open private molds (Aluminum Extrusion or ABS Vacuum Forming). We sign an NDA (Non-Disclosure Agreement) to guarantee we will never sell your design to anyone else.

5. Logistics & DDP Services: We Handle the Headache

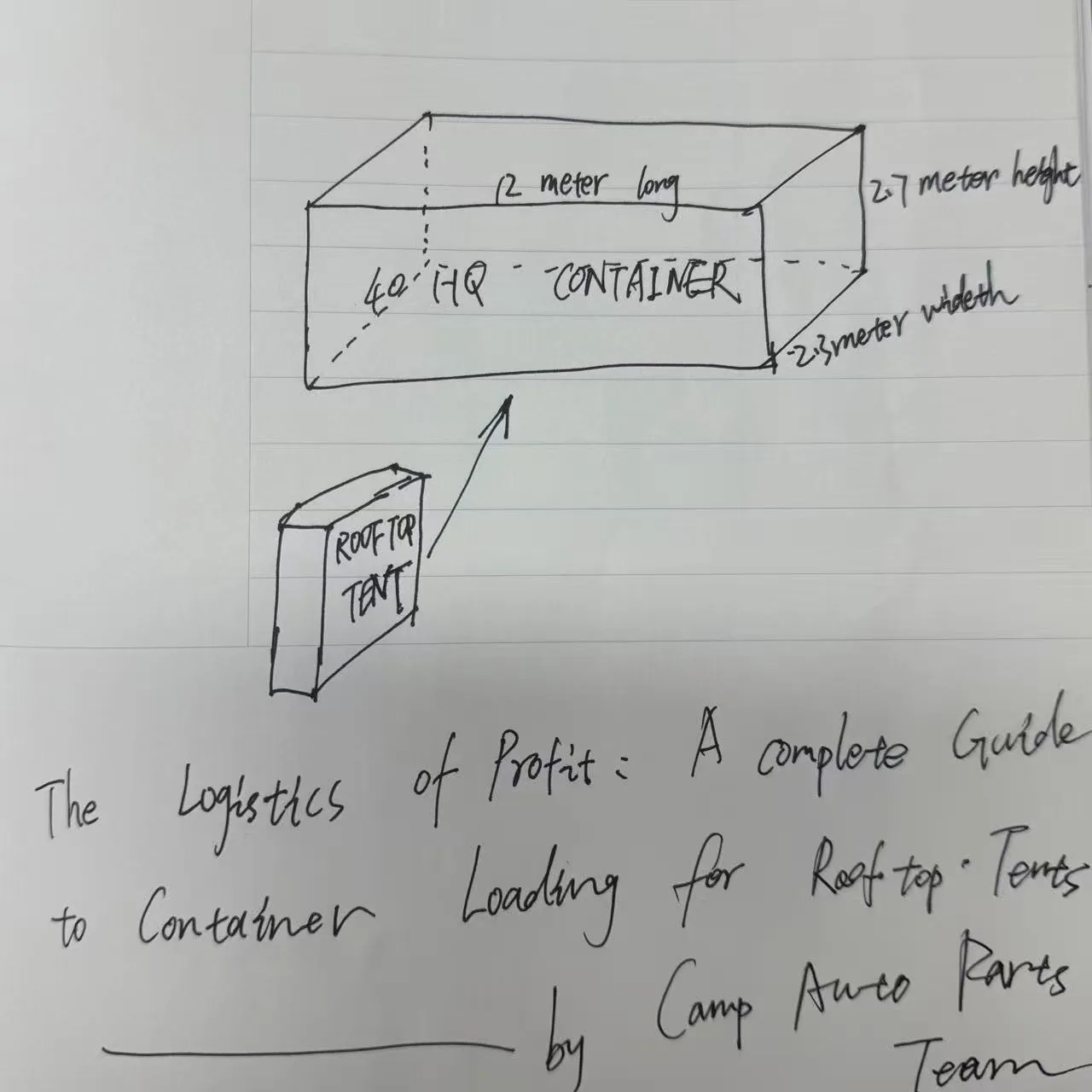

Shipping a 70kg, 2-meter-long box is not easy. It’s “Ugly Freight.” But we are experts at it.

5.1 Shipping Options

FOB (Free On Board): We deliver to Ningbo/Shanghai port. You handle the rest. Good if you have a forwarder.

DDP (Delivered Duty Paid): The “Hands-Off” option. We handle sea freight, customs clearance, tariffs, and truck delivery to your warehouse door in the US, Europe, or Australia. You pay one all-inclusive price.

5.2 Container Optimization (Tetris Logic)

Shipping air is expensive. We optimize loading plans.

Mixed Loading: We can stack heavy hard shell tents on the bottom and lighter soft shell tents on top.

Accessory Filler: We fill the gaps between pallets with high-margin accessories like Awnings, Annex Rooms, and Camping Chairs, effectively shipping them for free.

6. After-Sales Support: The 2% Rule

Our warranty rate is below 2%, but we prepare for the worst.

6.1 The Spare Parts Kit

With every container order, we recommend (and often provide) a “First Aid Kit” of spare parts:

Extra gas struts.

Replacement hinges.

Patch kits for fabric.

Extra ladder clips.

This allows you to fix minor customer issues locally and instantly, without waiting for parts from China.

6.2 Warranty Policy

2 Years on Shell and Frame.

1 Year on Canvas and Mechanisms.

Resolution: If a major defect occurs, we issue a credit note or ship a replacement unit. We don’t argue; we solve it.

Conclusion: Your Partner for Growth

Sourcing from China is a journey. You need a guide who knows the terrain.

Camp Auto Parts is that guide. We have the engineering depth, the manufacturing muscle, and the logistical brain to take your outdoor brand to the next level.

Don’t settle for a trader who marks up the price. Go direct. Go professional.

Ready to start?

Download our 2025 Catalog below and let’s schedule a strategy call.

FAQ: Common Sourcing Questions

Q: Can I order a sample to test quality?

Q: Do you support drop-shipping?