From Generic to Iconic: The 3-Stage OEM Guide to Customizing Your RTT Brand

By the R&D Director at Camp Auto Parts (Wuyi Camp Outdoor Products Co., Ltd.)

Introduction: The “Me-Too” Trap

Open Amazon or any 4×4 accessory site. What do you see?

Dozens of roof top tents that look exactly the same. Same black shell, same grey fabric, same design. The only difference is the logo sticker.

This is the “Me-Too Trap.” When your product looks identical to everyone else’s, you are forced to compete on price. And competing on price is a race to the bottom that destroys your margins.

As a manufacturer, we see which brands succeed and which fail. The successful brands don’t just “buy” tents; they design them.

At Camp Auto Parts, we offer a 3-Stage OEM Customization Program. Whether you are a startup testing the water or an established brand ready to dominate the market, here is how we can help you build a product that stands out.

Stage 1: Visual Identity (The “Low Risk” Entry)

Perfect for: Startups & First-Time Importers

MOQ: Low (10-20 Units)

You don’t need to spend thousands on new molds to look different. Stage 1 is about applying your brand’s “skin” to our proven, battle-tested tent models.

1. The Fabric Color Strategy

Most factories only stock Grey or Green canvas. We do more.

Trend Alert: We are seeing a huge surge in “Tactical Black” and “Burnt Orange” (Terracotta) for the US market.

Our Capability: If you can provide a Pantone code, we can dye the 280g Poly-Cotton canvas to match your brand identity exactly.

2. Logo Execution

Don’t just slap a cheap sticker on the shell. It looks unprofessional.

Silk Screen: Clean, large branding on the tent body or rainfly.

Laser Cutting: For a premium look, we can laser-cut your logo into the stainless steel hinges or mounting brackets. This screams “Quality” and cannot be peeled off.

Metal Badging: We can rivet an embossed aluminum plate onto the hard shell, similar to car branding.

Stage 2: Functional Upgrades (The Value-Add)

Perfect for: Brands looking to increase Average Order Value (AOV)

MOQ: Moderate (50+ Units)

This is where you solve specific customer complaints. You take a standard tent and “mod” it at the factory level so your customer doesn’t have to.

1. The “Sleep System” Upgrade

The #1 complaint in RTT reviews? “The mattress is too thin.”

Your Move: Ask us to upgrade the standard 5cm foam to a 7cm High-Density Memory Foam mattress with a washable quilted cover.

The Marketing Win: You can now market your tent as the “Most Comfortable RTT on the Market.”

2. Integrated Lighting

Campers hate fumbling for flashlights.

Your Move: We can pre-install an LED Light Strip inside the roof of the tent, powered by a simple USB cable. It costs very little to manufacture but adds massive perceived value to the user.

3. Storage Solutions

Shoe Bags: We can sew custom double-layer shoe bags that slide into the tent’s base channel.

Cargo Rails: For hard shell tents, we can pre-install Roof Cross Bars (Load Rating: 75kg) so your customers can carry bikes or kayaks on top of the tent.

Stage 3: Deep Customization (The Moat)

Perfect for: Market Leaders & Innovators

MOQ: High (Requires Mold Fees)

This is the ultimate level. You are not just buying a product; you are creating Intellectual Property (IP).

1. Private Molding (The Game Changer)

If you want a hard shell shape that nobody else has, we need to open a new mold.

Aerodynamics: We can work with your designers to create a shell with a lower drag coefficient.

Texture: Instead of smooth plastic, we can create a “Rugged Texture” or a unique geometric pattern molded directly into the ABS or Aluminum shell.

The Process:

You send us a CAD drawing (or a napkin sketch).

Our engineers create a 3D render.

We produce a 3D-printed prototype for approval.

We CNC machine the steel mold.

The Benefit: Exclusivity. We sign an NDA (Non-Disclosure Agreement). We will never sell your mold design to another client. It is yours and yours alone.

2. Patented Mechanisms

Do you have an idea for a faster locking mechanism or a unique window design? Our R&D team in Wuyi loves a challenge. We have helped clients patent unique hinge systems that allow for more internal bedding storage.

The “Golden Sample” Process

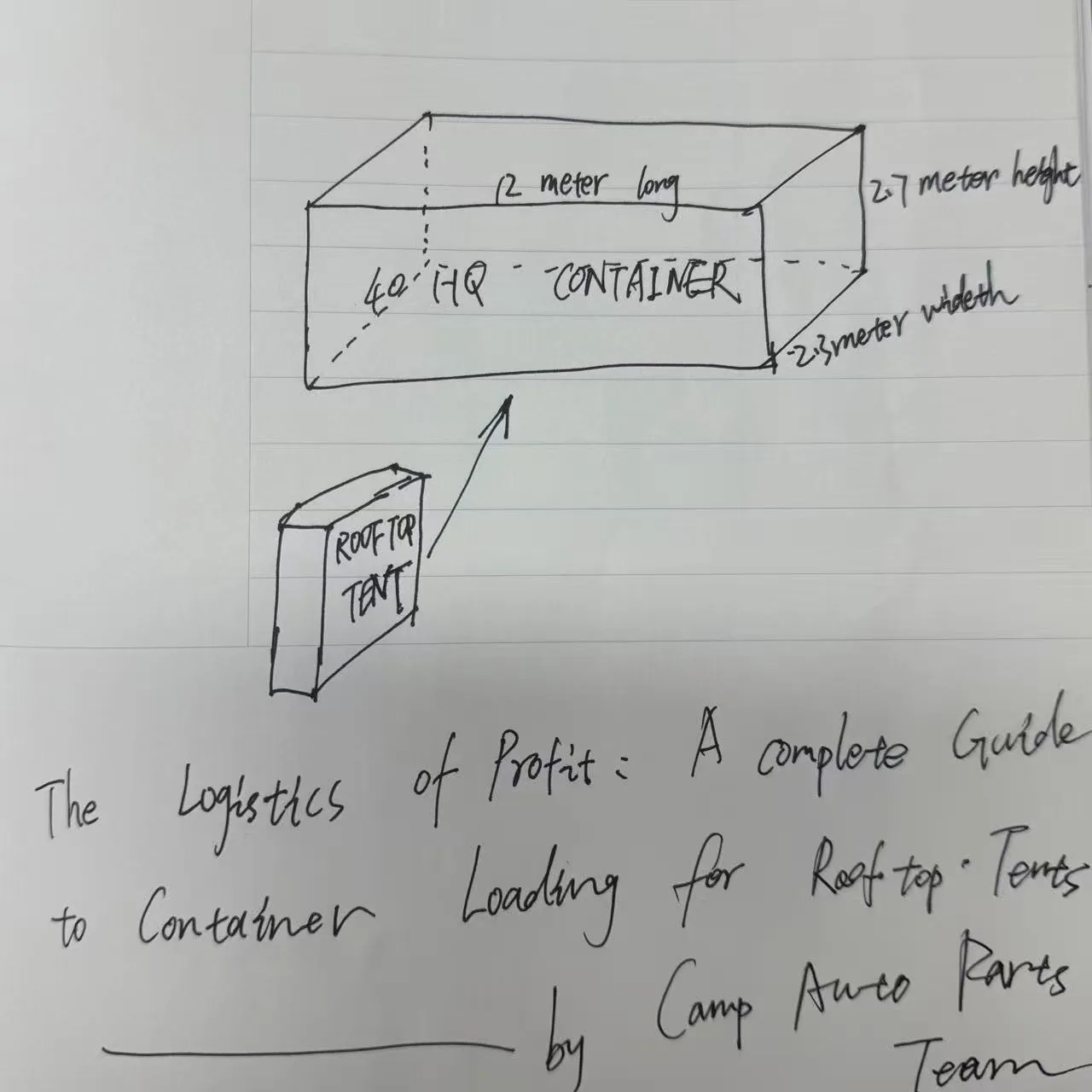

Before you commit to a 40ft container, you need confidence.

We practice the “Golden Sample” Rule.

The Spec Sheet: We document every single customization (Thread color #, Zipper brand, Logo size in mm).

The Prototype: We build one unit exactly to your specs.

Video Review: We do a live video call to measure and demonstrate the sample.

Shipping: We air-freight the sample to your office.

Sign-Off: You sign the sample. This becomes the “Golden Standard.” Every unit in mass production must match this sample perfectly.

Conclusion: Build A Brand, Not Just An Inventory

The world doesn’t need another generic roof top tent. It needs your vision.

At Camp Auto Parts, we are more than a factory; we are your product development engine. Whether you just want a cool logo or a completely new tent design, we have the machinery and the mindset to make it happen.

Ready to start your design journey?

Let’s discuss your specs.

👉 [Download Our OEM Customization Catalog]

(Includes color swatches, material samples, and mold pricing)

Email: info@campautoparts.com

WhatsApp: +86 181 5796 2741