The Economics of Importing: How to Lower Your Landed Cost per Roof Top Tent

By the Logistics & Export Manager at Camp Auto Parts (Wuyi Camp Outdoor Products Co., Ltd.)

Introduction: The Price Tag vs. The Real Cost

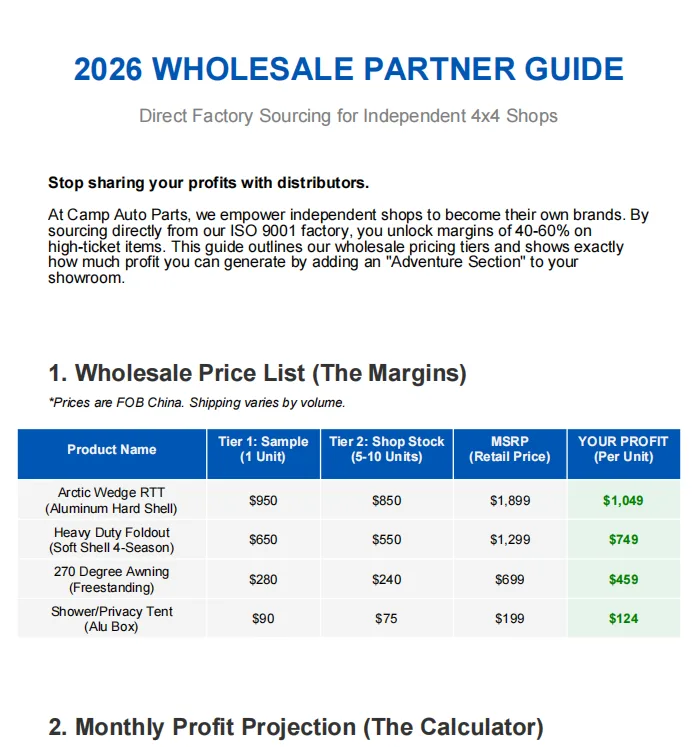

Let’s be honest. When you are sourcing Roof Top Tents (RTTs) from China, the first number you look at is the FOB Price (Free On Board).

You see a tent for $800, and you think, “Great, I can retail this for $2,500. That’s a huge margin.”

Stop right there.

The FOB price is just the starting line. By the time that tent arrives at your warehouse in California, Hamburg, or Sydney, the price has changed. Freight, duties, insurance, port fees, and “last mile” delivery can eat up 30% to 50% of your margin if you aren’t careful.

This is what we call the Landed Cost.

At Camp Auto Parts, we don’t just manufacture tents; we help you calculate and optimize the logistics. In this guide, I will show you exactly how we help our B2B clients squeeze more profit out of every container.

1. The Enemy is Volume, Not Weight

Understanding CBM (Cubic Meters)

Roof top tents are unique cargo. They are big, bulky, but relatively light compared to steel machinery.

In ocean freight, you rarely pay for weight; you pay for Space (Volume).

The “Air” Problem:

If you buy a standard hard shell tent that is 30cm thick when closed, you are shipping a lot of “air” inside that box.

Scenario A: A bulky tent design takes up 0.9 CBM.

Scenario B: A slim-line tent design takes up 0.6 CBM.

The Math:

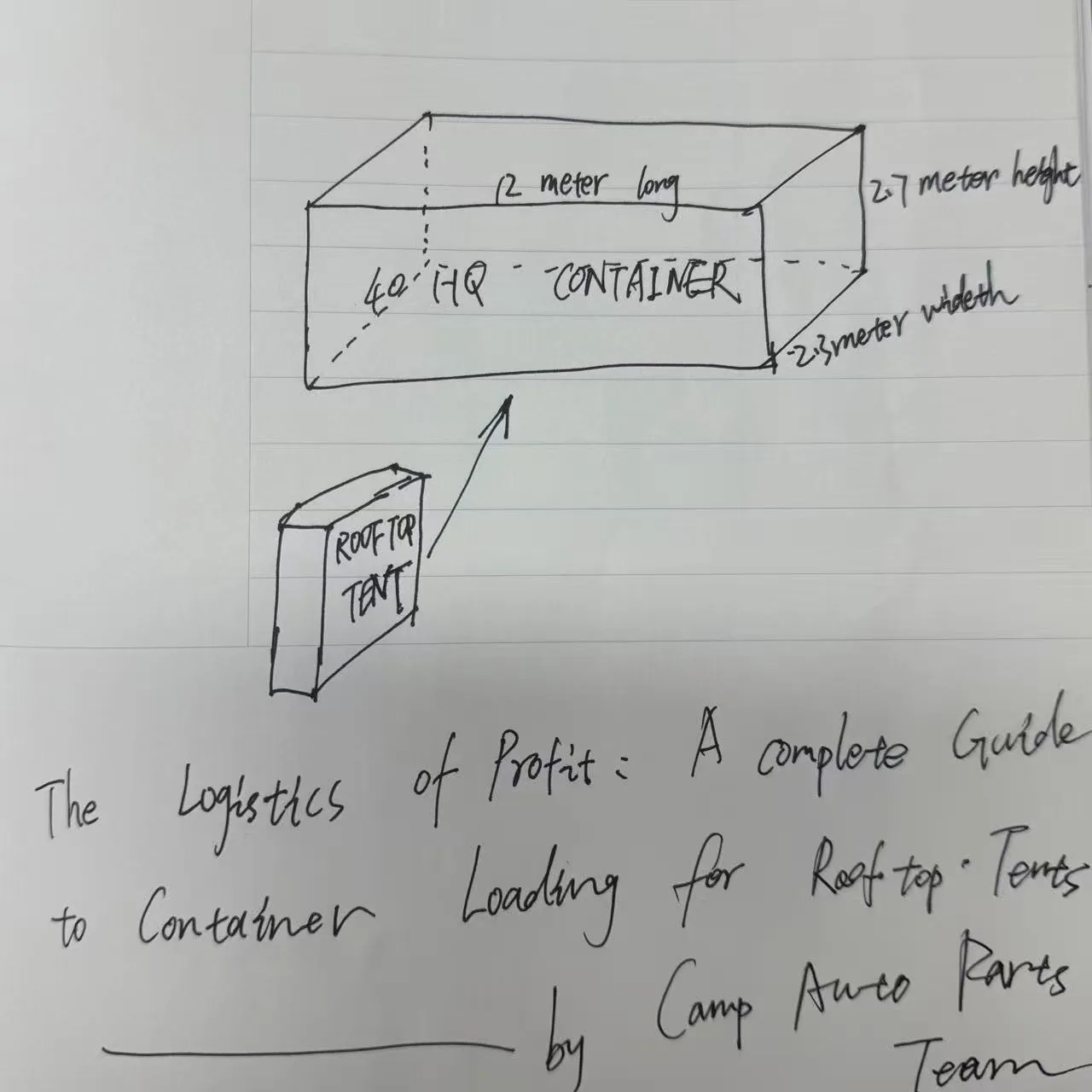

In a 40HQ container (approx. 68 CBM usable space):

Scenario A: You fit ~75 tents.

Scenario B: You fit ~110 tents.

If the container costs $5,000 to ship:

Scenario A Shipping Cost: $66 per tent.

Scenario B Shipping Cost: $45 per tent.

Result: You just saved $21 per unit purely by choosing a better packaging design. This is why our 2025 Ultra-Slim Series is a bestseller—it’s engineered for logistics.

2. Playing “Container Tetris”: The Mix Strategy

Don’t Ship Empty Corners

A shipping container is a rectangular box. Roof top tents are rectangular boxes. But they never fit perfectly. There is always “dead space” at the top or sides of the container.

The Amateur Mistake:

Shipping a container only containing Hard Shell Tents. Because they can’t be stacked too high, you might end up with 20% of the container empty near the ceiling. You are paying to ship air.

The Camp Auto Parts Solution:

We recommend a Consolidated Product Mix.

We utilize that “dead space” by filling it with high-density, small-footprint items from our catalog:

Titanium Camping Cups & Cutlery: These boxes are small and can fill gaps between pallets.

Car Awnings (2.5m): Long and thin, they slide perfectly along the container walls.

Pickup Bed Racks: These are flat-packed and heavy. We put them on the floor to lower the center of gravity and maximize weight allowance.

The result? Your shipping cost is spread across more products, lowering the per-unit shipping cost for the tents.

3. Navigating HS Codes & Duty Rates

The Compliance Factor

One of the most common questions we get is: “What is the HS Code for Roof Top Tents?”

Using the wrong code can lead to customs delays or overpaying taxes.

General HS Code: 6306.22 (Tents: Of synthetic fibers).

Note: Always check with your local customs broker as codes can vary slightly by country.

The Value of “Made in China”:

Depending on your country (e.g., Australia, Korea, ASEAN nations), China often has Free Trade Agreements (FTA).

We provide the necessary Certificate of Origin (Form E, Form F, ChAFTA) documents. This piece of paper can reduce your import duty from 10% down to 0%.

If your current factory isn’t offering you these certificates, you are literally throwing money away.

4. Packaging Engineering: The Hidden Cost of Damages

A Damaged Tent is a 100% Loss

Landed Cost isn’t just about shipping; it’s about Sellable Inventory.

If you import 100 tents, and 5 arrive with cracked shells due to poor packaging, your “Real Cost” for the remaining 95 tents just skyrocketed.

Our “Logistics-Proof” Packaging:

We don’t just use cardboard. We use a “Box-in-Box” system reinforced with:

Hard Plastic Corner Guards: To protect against forklift impacts.

EPE Foam Spacers: To create a “crumple zone” between the carton and the tent shell.

Palletization: For LCL (Less than Container Load) orders, we always palletize. Never ship loose boxes.

5. MOQ vs. Shipping Efficiency

Why Ordering 10 Units is Expensive

We support low MOQs (Minimum Order Quantities) for startups, but you need to understand the economics.

LCL (Less than Container Load):

If you order 10 tents, you share a container with other people’s goods.

Pros: Low capital investment.

Cons: Higher risk of damage (handling), higher port fees per CBM, and slower transit times.

FCL (Full Container Load – 20ft or 40HQ):

Pros: You control the seal. No one touches your goods until they reach your warehouse. Lowest cost per unit.

The Sweet Spot: If you can finance it, a 20ft Container (approx. 30-40 tents) is often the “Break-Even Point” where shipping costs become efficient enough to compete with big brands.

Conclusion: Let Us Do The Math For You

You are an expert in marketing and brand building. You shouldn’t have to be an expert in global logistics. That’s our job.

At Camp Auto Parts, we don’t just give you a price list. We provide a Loading Plan.

Send us your desired order list, and our logistics team will calculate:

Exact CBM volume.

How to optimize the mix to fill the container 100%.

Estimated Landed Cost advice.

Stop paying to ship air. sourcing smarter today.

👉 [Get Your Free Container Loading Plan]

Email: info@campautoparts.com

WhatsApp: +86 181 5796 2741