By the Senior Production Engineer at Camp Auto Parts (Wuyi Camp Outdoor Products Co., Ltd.)

Introduction: The “1% Defect” That Kills a Brand

In the outdoor industry, trust is hard to gain and easy to lose. Imagine this scenario: Your customer is on a 3-week overland expedition in the Australian Outback. It starts to rain. If a single seam on their roof top tent leaks, they aren’t just wet—they are stranded, angry, and writing a 1-star review that will haunt your brand for years.

As a procurement manager, you look at spec sheets every day. But spec sheets don’t tell the whole story. Two factories can both list “280g Canvas” and “Aluminum Base,” yet one tent will last 10 years, and the other will fail in 10 months.

Why? It’s all in the details.

At Camp Auto Parts, we believe in radical transparency. Today, I am taking you behind the scenes of our Wuyi factory to reveal the 7 most common manufacturing flaws in the RTT industry—and exactly how we engineer them out of your product.

1. The Base Failure: Plywood vs. Honeycomb

The Problem: The “Sponge” Effect

The floor of a roof top tent is its foundation. For years, the industry standard was marine plywood sandwiched between aluminum sheets.

The Flaw: No matter how well you seal it, wood is organic. Over time, temperature fluctuations cause micro-cracks in the seal. Moisture enters, the wood swells, and eventually, it rots. We call this the “Sponge Effect.” A rotting floor is a catastrophic structural failure.

The Camp Auto Parts Solution:

We have completely eliminated wood from our premium supply chain.

We use: Aviation-Grade Aluminum Honeycomb Panels.

The Science: Honeycomb structures offer the highest strength-to-weight ratio in engineering.

The Result: Our bases are 100% waterproof, mold-proof, and can withstand a static load of over 300kg (660lbs) without bending. Your customers can jump on it, sleep on it, and it will never rot.

2. The Waterproofing Lie: Coating vs. Taping

The Problem: Leaking Seams

Many factories claim “100% Waterproof,” but they only focus on the fabric itself.

The Flaw: When a sewing needle punches through canvas, it creates a hole. If you have 5,000 stitches, you have 5,000 tiny holes waiting to let water in.

The Camp Auto Parts Solution:

We treat waterproofing as a 3-stage defense system:

DWR Coating: The outer fabric is treated with a Durable Water Repellent to make water bead up and roll off.

PU Membrane: The inner fabric has a Polyurethane (PU) coating rated to 3000mm+ (twice the industry standard of 1500mm).

Hot-Press Seam Taping: This is crucial. We use industrial heat machines to fuse a waterproof tape over every single seam inside the tent. We periodically perform a “High-Pressure Shower Test” in our lab, blasting the tent with water jets to ensure zero leakage.

3. The Hinge Rust: Galvanized vs. Stainless

The Problem: Coastal Corrosion

Most overlanders love the beach. Saltwater is metal’s worst enemy.

The Flaw: To save roughly $3 per tent, some manufacturers use Galvanized Steel for hinges and bolts. It looks shiny when new, but after one season near the ocean, the zinc coating wears off, and red rust begins to eat the metal.

The Camp Auto Parts Solution:

We have a zero-tolerance policy for rust.

We use: 304 Grade Stainless Steel for all external hardware, gas struts, and mounting brackets.

The Test: We subject our hardware to a Salt Spray Test for 72 hours to simulate years of coastal exposure. If it corrodes, the batch is rejected.

4. The Condensation Trap: Designing Airflow

The Problem: Waking Up Wet (From the Inside)

Condensation is physics. When a warm body sleeps inside a cold tent, moisture forms on the walls.

The Flaw: Budget tents are sealed too tight without proper venting. The moisture has nowhere to go, dripping onto the sleeping bag by morning.

The Camp Auto Parts Solution:

We engineer “Passive Ventilation Systems.”

Flow-Through Vents: Our designs include upper vents protected by rain flies that stay open even during storms.

Anti-Condensation Mats: We highly recommend our B2B clients add our 3D Mesh Under-Mattress. This creates an air gap under the foam mattress, allowing moisture to evaporate instead of soaking into the bedding.

5. The Travel Cover: PVC Durability

The Problem: The Highway Shred

The travel cover takes the most abuse—UV rays, 70mph winds, bugs, and rocks.

The Flaw: Using standard 550g PVC. It feels thin and often cracks in freezing temperatures or fades to grey in the sun.

The Camp Auto Parts Solution:

We use: Heavy-Duty 680g/1200D PVC.

The Detail: We use high-frequency welding (not just stitching) for the cover seams to ensure the tent stays dry even if you are driving through a hurricane. We also use oversized YKK Zippers because struggling with a stuck zipper in the mud is a customer’s nightmare.

6. The Mattress: Density Matters

The Problem: The “Ground” Feel

A tent is only as good as its sleep quality.

The Flaw: Low-density foam (under 25 density) feels soft at first but compresses completely flat after 1 hour of lying on it. Your hip hits the hard aluminum base.

The Camp Auto Parts Solution:

We use: High-Density Non-Deforming Foam (30-35 Density).

The Feature: We wrap it in a washable, removable cotton cover. It provides firm support that mimics a home mattress, ensuring your customers wake up rested, not sore.

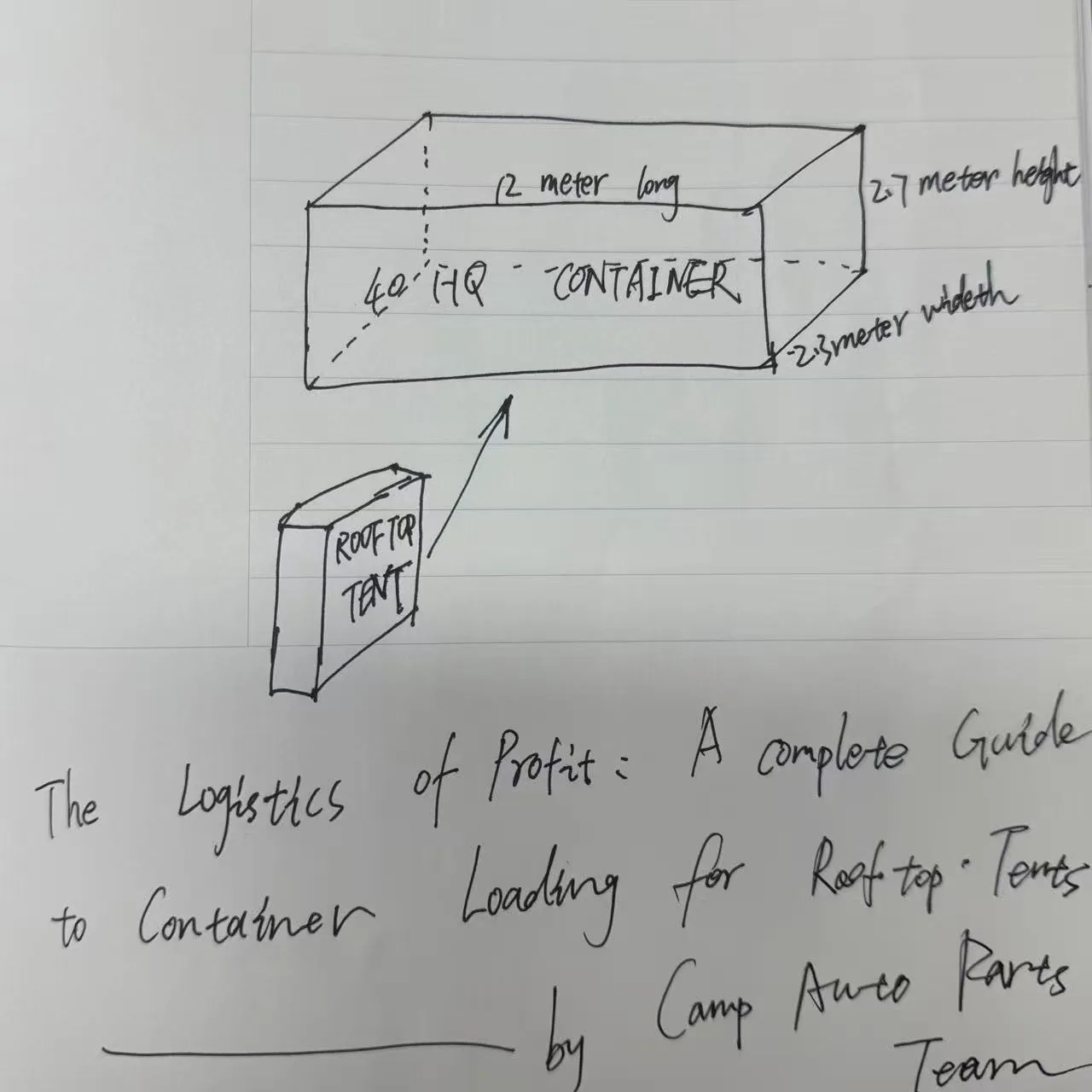

7. Packaging: The Last Mile Defense

The Problem: Forklift Damages

You pay for the product, shipping, and duties. If the forklift driver drops it, that money is gone.

The Flaw: Single-wall cardboard boxes with thin styrofoam.

The Camp Auto Parts Solution:

We pack for war.

7-Layer Carton: Impossible to puncture with a thumb.

Pearl Cotton (EPE) Armor: We don’t use brittle styrofoam (which cracks). We use EPE foam blocks that absorb impact shock.

Corner Guards: Hard plastic guards on all 8 corners of the box.

Palletization: For LCL (Less than Container Load) orders, we strap shipments to custom pallets to prevent mishandling.

Conclusion: Partner with a Factory That Cares

Quality control isn’t an accident; it’s a system. At Wuyi Camp Outdoor Products Co., Ltd., we don’t just build tents; we build reputation insurance for our clients.

When you are ready to scale your brand with a partner who understands the engineering behind the product, we are here.

Actionable Next Step for Procurement Teams:

Don’t take our word for it. Ask us for a Video Inspection. We will walk you through the production line on a live call and show you these 7 details in real-time.

👉 [Schedule Your Factory Video Tour]

Email: info@campautoparts.com

WhatsApp: +86 181 5796 2741